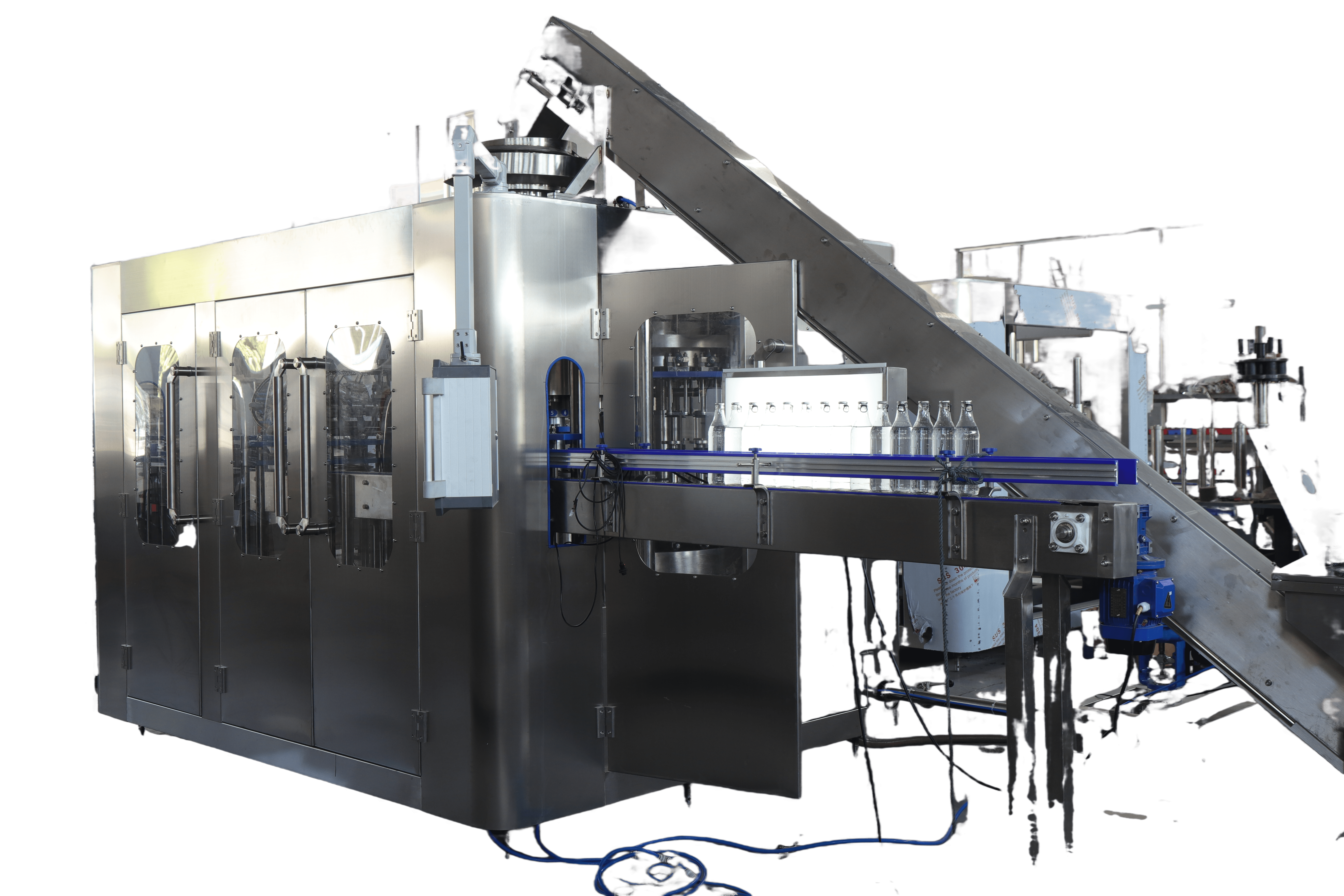

Oil Filling Machine

- Overview

- Related Products

Oil filling machine

Applicable Products: Peanut oil, Sunflower Oil, Olive oil

Suitable Container: PET bottles of various shapes and capacities

Filling Modes: Contact filling or non-contact filling

Production Capacity:up to 24,000 BPH

Technical specification

|

Model |

YGF 12 - 5 |

YGF 16 - 5 |

YGF 20 - 5 |

YGF 24 - 6 |

|

Bottle diameter ( mm ) |

50 - 200 |

50 - 200 |

50 - 200 |

50 - 200 |

|

Bottle height ( mm ) |

150 - 360 |

150 - 360 |

150 - 360 |

150 - 360 |

|

Air Supply Pressure ( Mpa ) |

0.6 - 0.7 |

0.6 - 0.7 |

0.6 - 0.7 |

0.6 - 0.7 |

|

Air consumption ( m3 / min ) |

0.5 |

0.5 |

0.5 |

0.5 |

|

Motor power ( KW ) |

2.57 |

3.55 |

4.56 |

5.54 |

|

Dimension ( mm ) |

1 6 0 0 * 2 4 7 0 * 2 4 0 0 |

1 8 0 0 * 2 2 0 0 * 2 4 0 0 |

2 1 0 0* 2 6 7*2 4 0 0 |

2 4 0 0*2 9 7 0*2 4 0 0 |

|

Weight ( kg ) |

2 0 0 0 |

2 2 0 0 |

2 5 0 0 |

2 8 0 0 |

Detailed description

This machine is used to produce various PET bottle edible oil,like peanut oil, sunflower oil,olive oil, lubricants,adopt piston filling,fill accurately without leakage,also can pack ketchup,peanut butter,honey etc.Unique filling head design and vacuum backdraft system ensure no residual oil drip leakage during filling process,fast and slow double-speed filling,adjustable filing speed,and eliminate bottle overflow phenomenon.Edible oil filling machine can be powered filling without the need to equip high-level tanks, which simplifies the installation process and improves filling efficiency.The cap screw driver adopts the no-load system of torsion adjustment to ensure that the cap will not be worn out by excessive force when the cap is tightened.Touch-screen interface friendly,simple operation,PLC control system,fast operation,stable performance,excellent quality.Electrical and pneumatic parts are made of high-quality components to ensure stable operation of the whole machine.

Advantages of the Automatic Liquid Filling Machine

High Efficiency: Automatic liquid filling machines significantly increase production speed and efficiency, reducing the time required to fill containers compared to manual methods.

Precision and Consistency: These machines ensure accurate and consistent filling volumes, minimizing product waste and ensuring uniformity across all filled containers.

Versatility: Designed to handle various types of liquids, from water and juice to more viscous substances, automatic liquid filling machines can be easily adjusted to accommodate different product requirements.

Hygiene and Safety: With automated systems, there is less human contact with the product, which enhances hygiene and reduces the risk of contamination. Additionally, safety features are often built into the machines to protect operators.

Scalability: Automatic liquid filling machines can be easily integrated into larger production lines and scaled up to meet increasing production demands.

Reduced Labor Costs: By automating the filling process, businesses can reduce labor costs and reallocate workforce to other areas of production that may require human intervention.

Ease of Operation and Maintenance: Modern automatic liquid filling machines come with user-friendly interfaces and require minimal maintenance, making them easy to operate and maintain over time.

Customizability: These machines can be customized to fit specific production needs, including different bottle sizes, shapes, and materials, providing flexibility for manufacturers.

EN

EN

AR

AR

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES

TR

TR