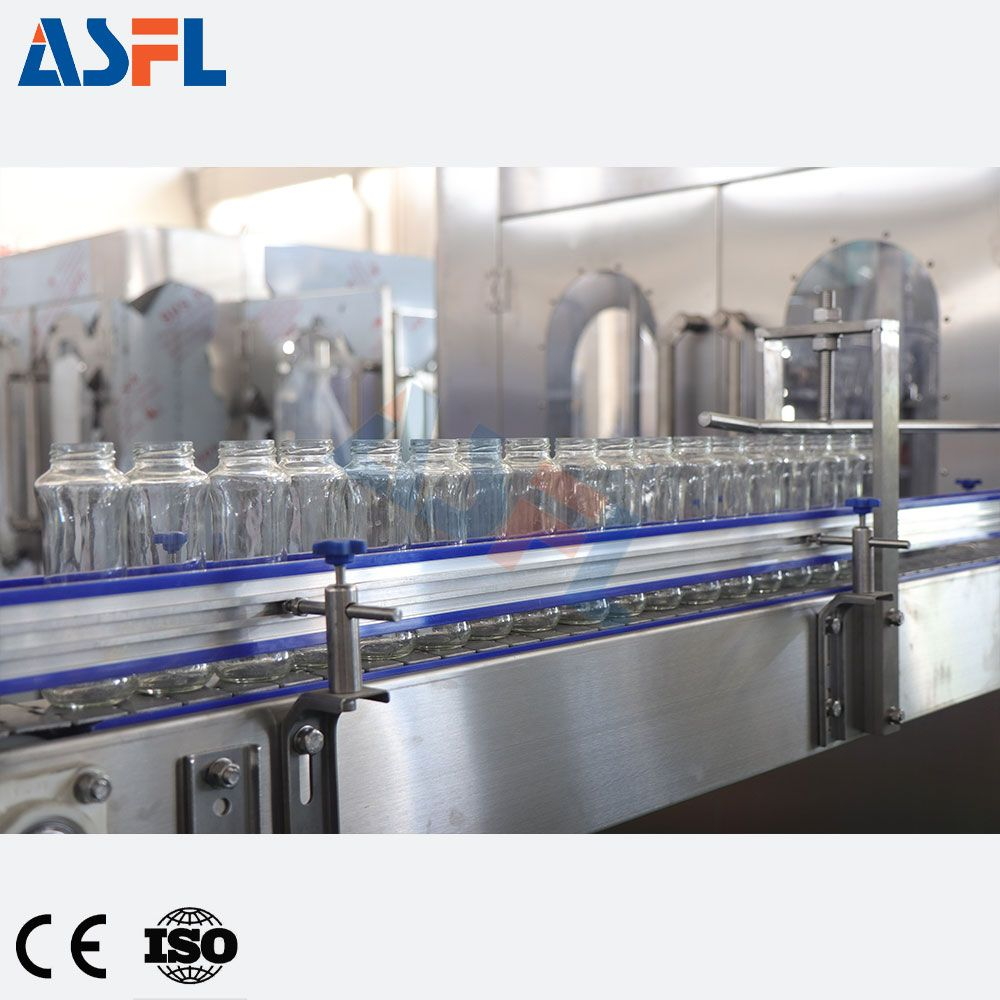

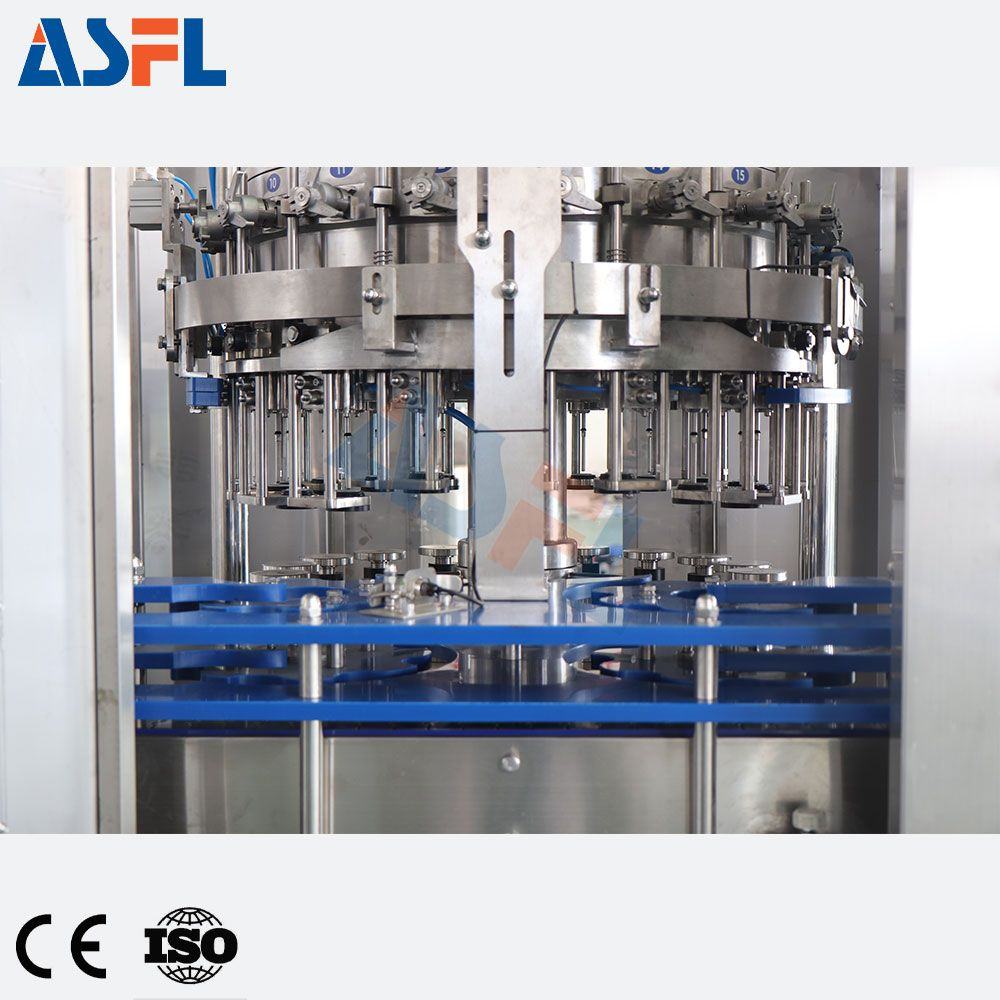

Hot Filling Juice Bottling Plant Quality and Productivity Hot Filling Juice Bottling Plant.

We proudly introduce our modern hot juice filling machine which has exceptional productivity and quality of output while ensuring uninterrupted workflow. This meets the varied requirements of the juice industry. Contains the keyword ‘Hot Filling Juice Bottling Plant’.

Get A Quote